What is E-beam Technology?

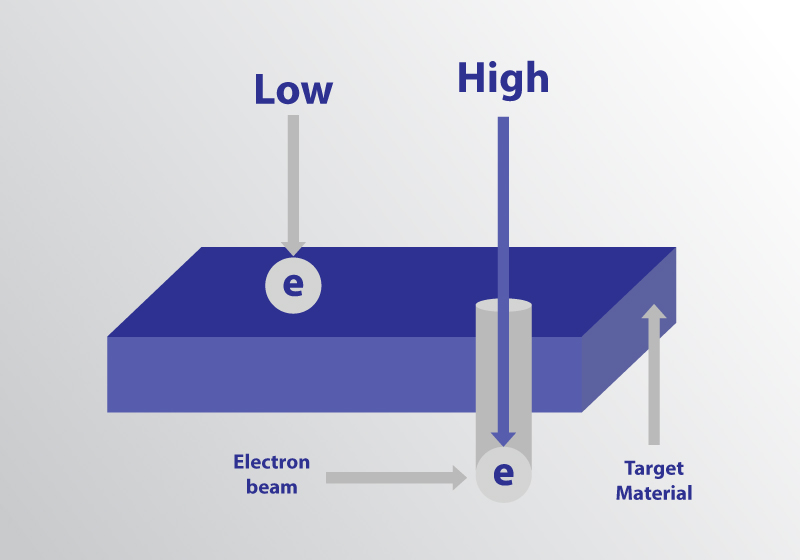

Electron Beam (E-Beam) technology is a process where a stream of high-energy electrons is accelerated and directed onto a target material. These electrons carry kinetic energy that penetrates matter and causes molecular-level changes — such as crosslinking, chain scission, sterilization, or color transformation.

It is a clean, green, and highly controllable technology with applications across diamonds, cables, polymers, medical devices, and food.

How It Works at Cromwell eBeam Solutions

At Cromwell eBeam Solutions, we operate a 3 MeV, 100 kW industrial electron beam

accelerator from NHV Corporation, Japan.

1. Electron Generation → Electrons are emitted from a heated tungsten filament(cathode).

2. Acceleration → These electrons are accelerated to 3 million electron volts (MeV) using a linear accelerator.

3. Beam Formation → The high-energy electron beam is scanned into a controlled curtain-like shape using magnetic deflection.

4. Material Exposure → Products (diamonds, cables, polymers) pass under the beam on conveyor systems or drum handling systems.

5. Molecular Interaction →

○In polymers: causes crosslinking (strengthening, heat resistance) or chainscission (controlled degradation).

○In diamonds: displaces atoms in the crystal lattice, leading to color centers

that produce fancy diamond colors.

○ In sterilization/food: breaks down DNA of microorganisms, ensuring safety

without chemicals.

Experience our advanced E-beam solutions tailored to your needs. Contact us to book a consultation or visit our facility

Applications of E-Beam Technology

E-beam technology is transforming industries by enhancing material properties and ensuring product safety. Key industries benefiting from our solutions include:

Diamond Irradiation

●Creates stable, vibrant fancy colors (blue, green, pink, orange, red).

●Precision dosimetry ensures consistent quality.

●Cromwell eBeam Solutions is a pioneer in this service in India.

- Cable Crosslinking

●Enhances heat resistance (up to 150–200°C).

●Improves mechanical strength, abrasion resistance, and chemical stability.

●Extends cable lifespan in solar, automotive, and industrial applications.

Polymer & Material Modification

●Improves wear resistance, toughness, and performance.

●Used in R&D for high-performance plastics and composites.

Food Irradiation (Future)

●Extends shelf life.

●Kills bacteria, insects, and pathogens.

●Retains nutritional value.

Medical Sterilization (Future)

●Sterilizes disposable medical devices (syringes, catheters, surgical kits).

●Safe, fast, and eco-friendly compared to ethylene oxide.

Why Choose Cromwell eBeam Solutions

India's Only Pure Service Provider

▼Cromwell eBeam Solutions is the only dedicated service-based electron beam facility in India — focused solely on irradiation services, not competing in product manufacturing.

Unmatched Material Privacy & Security

▶At Cromwell eBeam Solutions, your material is 100% confidential. With strict security protocols, we ensure every client's product is handled with the highest integrity and trust.

Cutting-Edge Infrastructure

▶Cromwell eBeam Solutions operates a 3 MeV, 100 kW NHV accelerator, roller conveyor, and advanced drum handling systems (1000–2000 mm, and soon 630–1000 mm) to serve industries at scale with world-class precision.

Proven Expertise in Diamonds & Cables

▶From fancy diamond color irradiation to cable crosslinking for enhanced performance, Cromwell eBeam Solutions has specialized experience across two of the most demanding industries.

Commitment to Innovation

▶With expertise in dose mapping, polymer crosslinking kinetics, and material modification, Cromwell eBeam Solutions delivers science-driven solutions with superior results.

Future-Ready Vision

▶Cromwell eBeam Solutions is expanding into food irradiation and medical sterilization, shaping the future of irradiation services in India.